Why our clients like us…

We endeavor to increase our customer’s expectations continually. Just ask for more!

Electrical & Electronic

Go to Daily Deals SectionDC & AC High Voltage Tester / Current Tester

All types of AC-DC-Merged High Voltage/Current testers as per requirements and range of KVA:-

The DC/AC High Voltage tester provides ideal condition to test any cable for its capability to withstand high DC voltage

The Instrument consist of

Cable Fault Detector Machine TDR

Cable fault Location system (various technology)

The Cable Fault Locating System COMPAC 32 is used to perform DC high pot test, Pre-location of fault distance with the help of pre-locator unit and

Pin-point underground cable fault in acoustic method with the help of suitable Surge wave receiver and Pin-point sheath faults in power transmission and

distribution networks or service provider companies. Key features Operating Mode Surge, Arc / SIM, DC / Proof Test/ Pre-location and Sheath Fault

Pin-point location of cable faults in Low, Medium and High voltage cables by acoustic method.

Perform DC / Proof test up to 32 kV

DC Test Current 10/20mA

Burn test up to 32 kV – 60mA for short period

Surge Output voltage selectable in three ranges 8, 16 and 32 kV continuously variable

Full energy delivering capacity at each select range.

High Surge energy of 1000 Joules (optional 2000J)

Single Impulse and 1.5, 3 and 6 seconds intervals or as per customer request

Pre-location of cable faults distance with TDR, ICM, SIM/MIM & Decay mode.

Big LCD touchscreen color display.

Maximum measuring pre-location range up to 64km

Sheath fault location up to 8kV – 60mA

Protection Class – IP 54

LCR Measuring Instrument / Digital LCR Meter for Measuring

Basic Accuracy: 0.3 %

Measuring Rate: 3 meas / sec

Correction Function: Open / Short multi – frequency Zeroing

Display Mode: Direct, D %, D ABS

Display: 20 ́ 2 Characters LCD with Back – light

Operation Temperature and Humidity: 0°C 40°C, £ 90%RH

Power Requirements Voltage:

Ultrasonic Distance Meter for Distance Measurement

With up to 15 meters range and high precision our Ultrasonic handheld distance measurement system is a key to productivity. When the area of work and measurement to be performed are too tight to maneuver this handheld laser class 2 meter can indeed a be friend.

Coating Thickness Gauge

A digital coating thickness gauge (also brought up as a paint meter) is employed to live dry film thickness. Dry film thickness is maybe the foremost critical measurement within the coatings industry thanks to its impact on the coating process, quality and price. Dry film thickness measurements is accustomed evaluate a coating’s expected life, the product’s appearance and performance, and ensure compliance with a bunch of International Standards.

Digital Ultrasonic Thickness Gauge KM 8041

A coating thickness gauge (also brought up as a paint meter) is employed to live dry film thickness. Dry film thickness is maybe the foremost critical measurement within the coatings industry thanks to its impact on the coating process, quality and price. Dry film thickness measurements is accustomed evaluate a coating’s expected life, the product’s appearance and performance, and ensure compliance with a bunch of International Standards.

AC Current Clamp Adapter Meter CA300

This is AC Current Clamp Adapter Meter CA300 which is made by utilizing optimum quality raw material and the latest technology. In line with industry-standard, we provide the entire range in various customized options and at affordable prices.

True RMS Digital Insulation Multimeter

True RMS Digital Insulation Multimeter is a true RMS device (RMS means root mean square) is tool which can measure alternating current (ac) or ac voltage. Also it is used to check electrical circuits for faults.

True RMS Digital Insulation Multimeter is much more accurate than RMS when measuring AC Current.

Digit Large Display Digital Clamp Multimeter With Terminal Locking System

These are Digital Multimeter with 3 ½ Digit Large Display and with terminal locking System.

Looking for Digital Clamp Multimeter? Read more about the features of Digital Clamp Multimeter & make an informed choice to buy at the best price online.

True RMS Multi Parameter Mobile Logger Digital Multimeter KM 525 | Multimeter True RMS

True RMS Multi Parameter Mobile Logger Digital Multimeter KM 525 | Multimeter True RMS

These are True RMS Multi Parameter Mobile Logger Digital Multimeter with 4 digit display. It has 17 functions and 69 Ranges. It has 2 year of warranty and Dc voltage accuracy of 0.08%. Also it has 9 Volt Battery.

Tools & Cable Components

Go to Daily Deals SectionTip and Die

Cable Extrusion tip and dies in Italy from us are designed to your specification as per the requirement, with the lowest MOQ and frequency of order. Ask for free samples anytime.

| DESCRIPTION (MATERIAL: HASTEALLOY) |

| COMPRESSION TIPS |

| SEMI-COMPRESSION TIPS |

| TUBING TIPS |

| EXTRUSION DIES |

| DESCRIPTION (MATERIAL: SS440C) |

| COMPRESSION TIPS with TC (Tungsten Carbide) insert |

| SEMI-COMPRESSION TIPS |

| TUBING TIPS |

| EXTRUSION DIES |

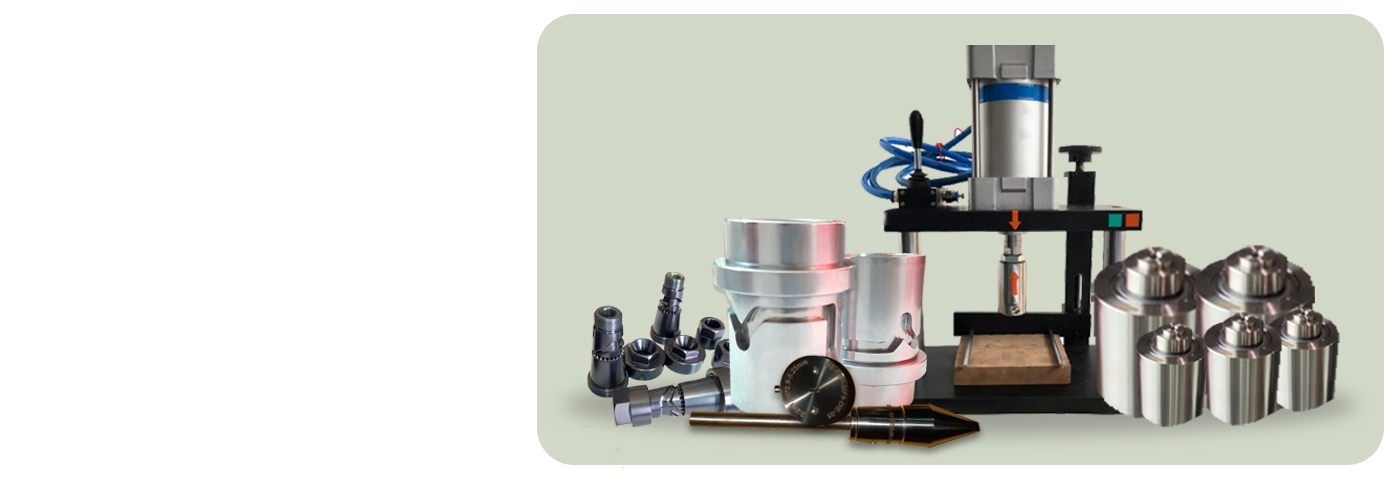

Multi Die – Hydraulic Press Machine for Making Sample Molds

Multi Die – Hydraulic Press Machine for Making Sample Molds

A hydraulic press is a multi-use device as it can be used to mold the plastic samples for several testing requirements as well as day to day inspection such as Color matching tabs can be made with it, Limiting oxygen index test samples as per ISO 4589 can be prepared. The use of it is quite simple, but the granules on the dies of expected shape and press it on prescribed temperature, and within some minutes you get your sample as required.