Cable Cost optimization-Cable and plastic test system for manufacturers-Part 2 Leave a comment

Investment in cable and plastic test equipment and return on investment to achieve cable cost optimization.

What matters most in manufacturing?

- Attracting customers with optimum quality exactly meeting the expectation of clients.

How to achieve?

More accurate data and measurement with flexible and reliable connectivity brings a product more and more near to the client’s expectation. This way one saves costs and increases expectations.

So the Key is Accurate and fast measurement.

- Digitalization in factories using IoT-what is the basis of it?

Basis of Digitalization in Factory is an accurate data definition and measurements. For example, if a company itself does not know how much fire retardant it Category B2ca cable is, how it can start a project of digitalization in order to standardize the mixing process of raw material and processing parameters on extrusion?

The key is knowing where you are and what tolerance we have in hand to play with.

- How measuring instruments could be affordable for all?

Companies with high brand value charges at least 30 % of their total cost to clients JUST FOR MARKETING & BRAND BUILDING, who pays at the end is the Client for other’s marketing. Whereas what you wanted to pay for is just the Instrument with high accuracy, reliability, and speed?

This is the reason today in the industry several manufacturers are just too behind the benchmark and never been able to finance required investments for those good instruments and machinery cause they are far more expensive than the expectations.

The key is to ask for quotations, give chance to new players, and compare their performance/price with existing BRANDs.

Note:- Of course some ideal and theoretical conditions are taken into account on the above example but in a practical way this calculation can be easily done by any manufacturer and they can realize themselves what would be the best possibility.

Case study 01:-

Cable manufacturing company XYZ in Italy wants to produce CPR grade B2ca Control cables 4G 2.5 sqm, with HFFR X Insulation and sheathing. The cost of per meter cable is 20€ and another costing is as follows:-

Overhead:- 6€/meter

Additional costs (altogether to make calculation easy:- 4€/meter

| The total cost of Cable: | 30€/meter |

| Customer is willing to pay: | 40€/meter |

| GP (and %): | 10€ (33.3%) | ||

| EBITDA | 3€ /meter | ||

| After-Tax | Net Profit | 1.8 €/meter |

With this steep net margins, it would be impossible to sustain for XYZ so the management asked its middle management to work upon cost reduction (however material and overhead are already optimized)

90 days of delivery is normal for such cables as it has to be first prepared as a prototype then wait 2 months for the approval from the third party on several testing and then start the production at a series rate.

90 days of delivery is just because of third party tests required and wait for approval whereas it also causes cash crunch and inflow issues to the company itself as customers will pay as soon as the delivery packing list is prepared (let us assume).

Option 1:- Manufacturer can have a fully certified in-house laboratory and test and approve everything by itself in order to reduce delivery time by 2 months (Almost impossible as CPR could not be approved internally for B2Ca grade, secondly the huge investment will still cause an increase in depletion costs of 0.5% to 1% in OR-II).Know more here.

Option 2:- Manufacturer can invest in Simulating Laboratory with OPTIMAL accuracy and certification which costs about half of the option 1, and still continues the production as they now know that it would pass, while testing all prototypes in house and simultaneously keeps manufacturing ON while the samples (less than usual) is being tested in third party lab for approval. In this way, they can reduce delivery/invoicing time from 90 days to 30 days while just increasing the depletion rate of 0.25%-0.5%. It adds a financial credit of 1%-1.5% itself which in consolidation gives around 1% of the increase in Net profit to achieve cable cost optimization through cable and plastic test equipment investment.

This way ROI of simulator testing Lab can be less than 24 months.

Of course some ideal and theoretical conditions are taken in to account on the above example but in a practical way this calculation can be easily done by any manufacturer and they can realize themselves what would be the best possibility.

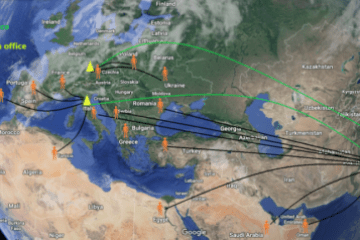

Techtrivial helped several cable and plastic manufacturers in such calculation and setup of optimum required laboratory or machinery for them throughout the LA-EMEA region.

This is just a case study, we have several such cases where with the help of just a few Cable and plastic test equipment, companies are able to save cost in millions and to be specific from 0.5-4% of OR-II. Below are some examples:-

- Conductor resistance and Copper purity test measuring device- The kelvin bridge Ohm meter also call CR Meter helps you to fine-tune the gap between actual conductor resistance and 100% of the required specification.

https://www.techtrivial.com/product/copper-purity-test-apparatus/

- Weighing balance and density meter- Helps you to track your weight analysis, not only of plastics but also the finished goods and conductors.

https://www.techtrivial.com/product/profile-projector-cable-measurement/

- HV tester- helps you to prevent complaints and failures on-site which in turn becomes much more expensive at a later point of time.

https://www.techtrivial.com/product/dc-ac-high-voltage-current/

- Insulation resistance (Volume resistivity) measurement- Helps to predict the requirement vs actual insulation properties of plastic in real conditions.

https://www.techtrivial.com/product/lcr-measuring-in…asic-to-advanced/

- Correct Extrusion tip and dies- Are the main component what plays a huge role in keeping the diameter and thickness under control along with reducing surface issues and scrap afterward.

https://www.techtrivial.com/product/tip-and-die/

There are many more, we are sure to put all the case studies one by one in the coming time. Till then remember that www.techtrivial.com is your one-stop-shop for all laboratory aids and cable and plastic test equipment supplies. Very soon we are launching our Industry 4.0 compliant ERP system on Microsoft 365 base specifically designed for the Cable manufacturing industry. Stay tuned…stay optimized. 🙂