Natural Gas Safety Valve (Socket)

Natural gas safety valve with a thermal device and quick connection. Available with a steel safety device (resistant up to 925 degrees), and with the brass safety device (resistant up to 650 degrees).

Also available without a thermal safety device.

Related products

-

General & Physical Tests

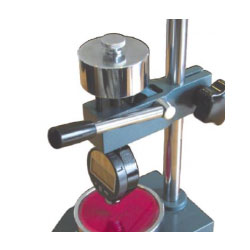

Shore A and D – Hardness Tester

0 out of 5(0)The hardness tester is used for understanding the suitability of plastic compound material such as PVC, LSZH, EVA, PE, etc.

The test itself becomes very important when it is crucial to decide the temperature profile and tensile strength required for the product in the design phase. The hardness of the compound also determines flexibility of cable up to some extent.

SKU: n/aThis product has multiple variants. The options may be chosen on the product page -

General & Physical Tests

Thermal Stability Test | Thermal Balance Test

0 out of 5(0)Thermal Stability Test is used for materials like wire, cable, soft PVC, plastic insulating sheath, etc. It is tested at 200 Degrees Celsius ± 0.5 Degrees Celsius. It is made according to GB/T2951.7-1997 standards.

It comes with accessories included :

- test tubes as per IEC 60811-405

- PH litmus paper

SKU: n/aThis product has multiple variants. The options may be chosen on the product page -

General & Physical Tests

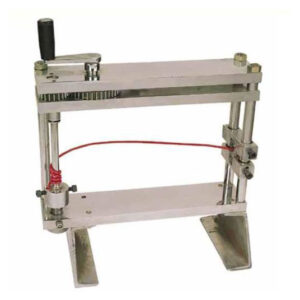

Cold Bend Test | Cold Impact Test

0 out of 5(0)IEC 60811-504 describes the cold bend test method for cables under low temperatures. The cold bend test on cable is only possible upto a maximum diameter of 12.5mm. The test is mainly conclusive to understand the flexibility and strength of plastic used over cable under low temperatures.

Whereas cold impact test on cables is performed according to IEC 60811-506. This test is mainly designed to simulate the plastic’s capacity to resist mechanical shock under cold environment.Here from a certain height, mandrels of specific weight are dropped on the cable.

SKU: n/aThis product has multiple variants. The options may be chosen on the product page -

General & Physical Tests

Multi Cell Ageing Oven (IEC & UL2556 Compliant)

0 out of 5(0)Multicell Ageing Ovens (with or Without HMI-PLC control)

Each Cell is a complete instrument in itself i.e., fitted with individual Temp. Indicating Controller, Air Flow Meter, Air temperature controller and an

Hour Meter. This enables the user to test different type of samples at desired temperature and duration, depending upon test requirement of end users

& testing authorities.

The instrument consists of the following:

• Double walled chamber with inside chamber of thick aluminum sheet. Size of the chamber is 10 cm x 30 cm

• Digital Temp. Indicating Controller with sensor. Temp. range 0-200 ± 2 o C

• Digital Flow meter for monitoring the volume of air passing through the chamber.

• Air inlet nozzle for the airline or air compressor.

• Specially Designed heaters to heat the air before it enters the cell

• Separate temperature controllers for air temperature control

• Air turbulence fan with motor to rotate at 60 RPM (Air source has to be provided by User)

• Specially designed cover to hold three to five test samples in each chamber.

• Timer System to record the total time of test.SKU: n/aThis product has multiple variants. The options may be chosen on the product page