Hot Set Test | Heat Pressure Test

Hot Set Test and Heat Pressure Test (with or With out HMI-PLC control):-

The instrument is manufactured as per the IEC specification and also confirms other international standards.

Hot Set Test | Heat Pressure Test

This test is used to determine whether the material used in insulation is sufficiently crosslinked or not. The purpose of this test is clearly to assess the degree of crosslinking achieved in the plastic used for extrusion.

The test result informatively shows the extent of crosslinking between Carbon and hydrogen molecules of a hydrocarbon used as plastic here.

The norm suggests using dumbbell samples marked with 20 mm or 10mm distance in the middle of the sample equally distant from the center.

Upon putting the samples with prescribed weight, temperature, and clips to hang and time required, the elongation is measured in the sample to understand the degree of crosslinking.

Afterward, it is also possible to do a permanent set test of the same sample to evaluate the thermoset behavior of the plastic used. It is noted that the thermoset behavior depends on the crosslinking as well and it is directly proportional.

Every Tech Trivial product gives you exactly what you need: accurate measurements, consistent, reliable performance, best possible safety, and best possible warranty available.

Standard Compliance:

It is made according to EN 60811-507, EN 60811-501, and IEC 50811-507 test standards.

Our EN 60811-507 compliant hot set test ovens have different types.

- With Laser guided gauge and automatic reporting system (Through HMI)

- With manual scale measurement and reporting

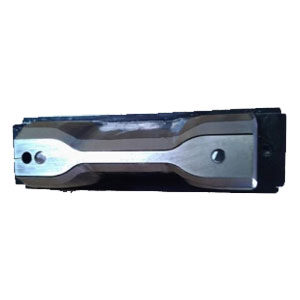

Model No.: D1015

Specifications:

Hot Set Test and Heat Pressure Test (with or Without HMI-PLC control):-

The instrument is manufactured as per the IEC specification and also confirms other international standards. The instrument contains:-

• A double-walled cabinet with the inside chamber of stainless steel

• Inner dimensions of the chamber are 30 cm x 50 cm 20 cm (W x H x D).

• Full view glass Door to observe the specimen under test.

• Temp. Range 250 ± 2 o C. at sensor point.

• The oven is designed to give 8 to 20 air changes per hour.

• An Digital air flow meter is fitted to monitor the airflow rate. Range 0- 10 LPM, LC-0.1 LPM

• Grips are provided at the top of the oven to hang specimen/s.

• Suitable weights up to 1 kg are provided with the provision to attach the weights to one end of the test pieces.

• Two ultrasonic sensors combined with laser pointers are given on the front door.

• Laser pointers are attached to facilitate the operator to take an exact readings of the sample elongation.

• A blade is provided in the oven to cut the sample to remove the tensile force without opening the door.

You can also check our more Machinery Products.

Based on 0 reviews

Be the first to review “Hot Set Test | Heat Pressure Test”

You must be logged in to post a review.

You may also like…

-

General & Physical Tests, Machinery, Tools & Cable Components

Multi Die – Hydraulic Press Machine for Making Sample Molds

General & Physical Tests, Machinery, Tools & Cable ComponentsMulti Die – Hydraulic Press Machine for Making Sample Molds

A hydraulic press is a multi-use device as it can be used to mold the plastic samples for several testing requirements as well as day to day inspection such as Color matching tabs can be made with it, Limiting oxygen index test samples as per ISO 4589 can be prepared. The use of it is quite simple, but the granules on the dies of expected shape and press it on prescribed temperature, and within some minutes you get your sample as required.

SKU: n/a

There are no reviews yet.